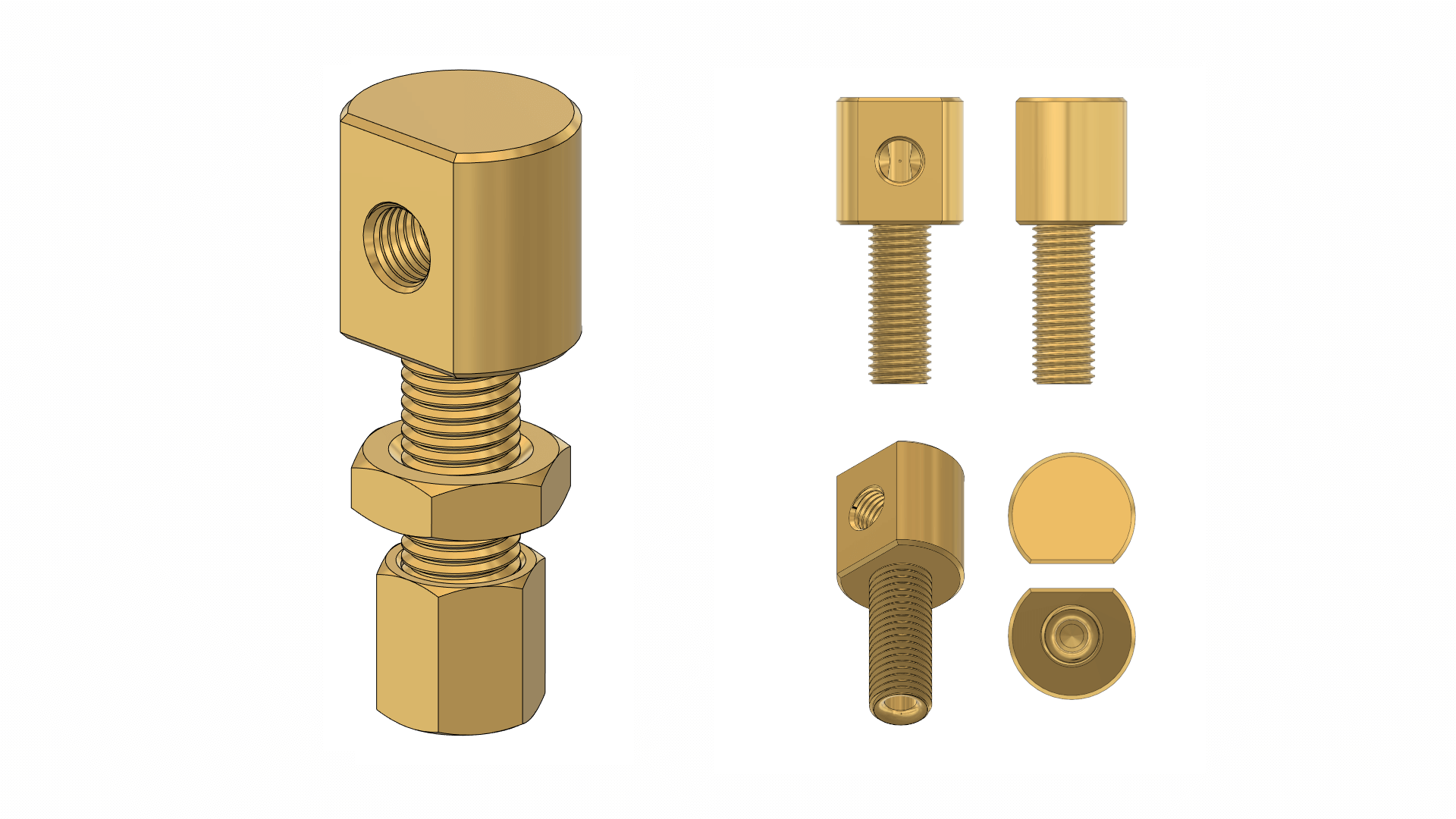

A metric replica of Station Road Steam’s Blower Pipe Smokebox Fitting (part no. 10234-B).

Unfortunately, I was not able to obtain the part from Station Road Steam itself, so I had to make one myself. In contrast, my metric version has the feature to fit a compression ring fitting (DIN EN 1254-2) instead of a union nipple/nut at the inside (where the J-pipe connects to). But you can of course manufacture this according to your own needs or preferences.

On my Feldbahn I use this smokebox fitting to guide the air pump ’s exhaust steam up the chimney, making use of it to sustain the fire.

Materials & Parts

- 16 mm brass round stock

- bulkhead compression ring fitting (KSV 4 MS, optional)

Manufacturing

Pretty simple and nothing fancy, and you have two options – you can make use of the bulkhead compression screw fitting, the smokebox fitting is then manufactured from two parts, otherwise it’s one lathe-turned part.

If you use the stock bulkhead fitting, you have the advantage that you already get a matching lock nut as well as the compression ring and nut. But you have to silver solder the bulkhead fitting and the custom-made part together after both are prepared.

If you turn the smokebox fitting from one piece, you can decide which connection system you’re going to use on the inside of the smokebox. The drawing in the downloads section shows a compression ring fitting.

Option 1 – Lathe-turned Part (one part)

There is not much to say, since it’s a pretty straight forward and non-critical part (in terms of dimensions) – see the drawing attached below. Turning, chamfering and threading the cylindrical part, then milling/filing the flat and drilling, tapping and chamfering on the flat.

Option 2 – With Stock Bulkhead Compression Fitting (two parts)

The stock bulkhead fitting is cut at the longer side of the part, to get an about 22 mm long threaded rod. After cutting, the cut face is turned square and turned down a bit larger than 6 mm (+ 0.1-0.3 mm) in diameter, about 2 mm along the turning axis. This later gives a 2 mm deep press fit which is additionally silver soldered.

The head of the smokebox fitting is made of a 16 mm long piece of the 16 mm brass round stock. After cutting to length, squaring the cut faces and chamfering the edges (about 0.5 mm at 45°), a 3 mm wide and 11 mm deep hole is drilled into the center along the turning axis. With a 6 mm milling cutter an about 2 mm deep hole is drilled into the same face. This later will take the (no longer) stock bulkhead fitting.

When both parts are ready and pressed together, they get silver soldered to become one part.

After this, the finishing of the part is pretty straight forward. Milling or filing the flat on the head. Drilling a centered 5 mm hole, tapping the M6x0.75 mm thread and chamfering the flat to match the other chamfers.