A day in steam doesn’t last forever, and sooner or later the fire gets removed. Besides a good amount of ash in the fire and the smokebox, the fire tubes are also covered with soot.

Components

Brush

The best way to get them clean again is to use a flue brush whose bristles are softer than those of the steel tubes but still hard enough to scrape off the dirt. It also could be a good idea if the material is somewhat heat-resistant. I figured brass (besides of steel and stainless steel) as the best choice available on the market to fulfill this purpose. The inner diameter of the Feldbahn’s tubes is a bit less than 14 mm – so I bought a brass brush (Lessmann Pipe Brush ) with a nominal OD of 14 mm.

Rod

The round brush (about 10 cm long) wouldn’t work on its own because you obviously can’t get it all the way through the ‘fairly’ longer tubes. So there has to be a rod to push and pull the brush through the tubes. I had a flexible rod with a wooden handle in mind and went on a search for it. The Holzbrink Twisted Sweep Rod came closest to what I had in mind.

Adjustments and Assembly

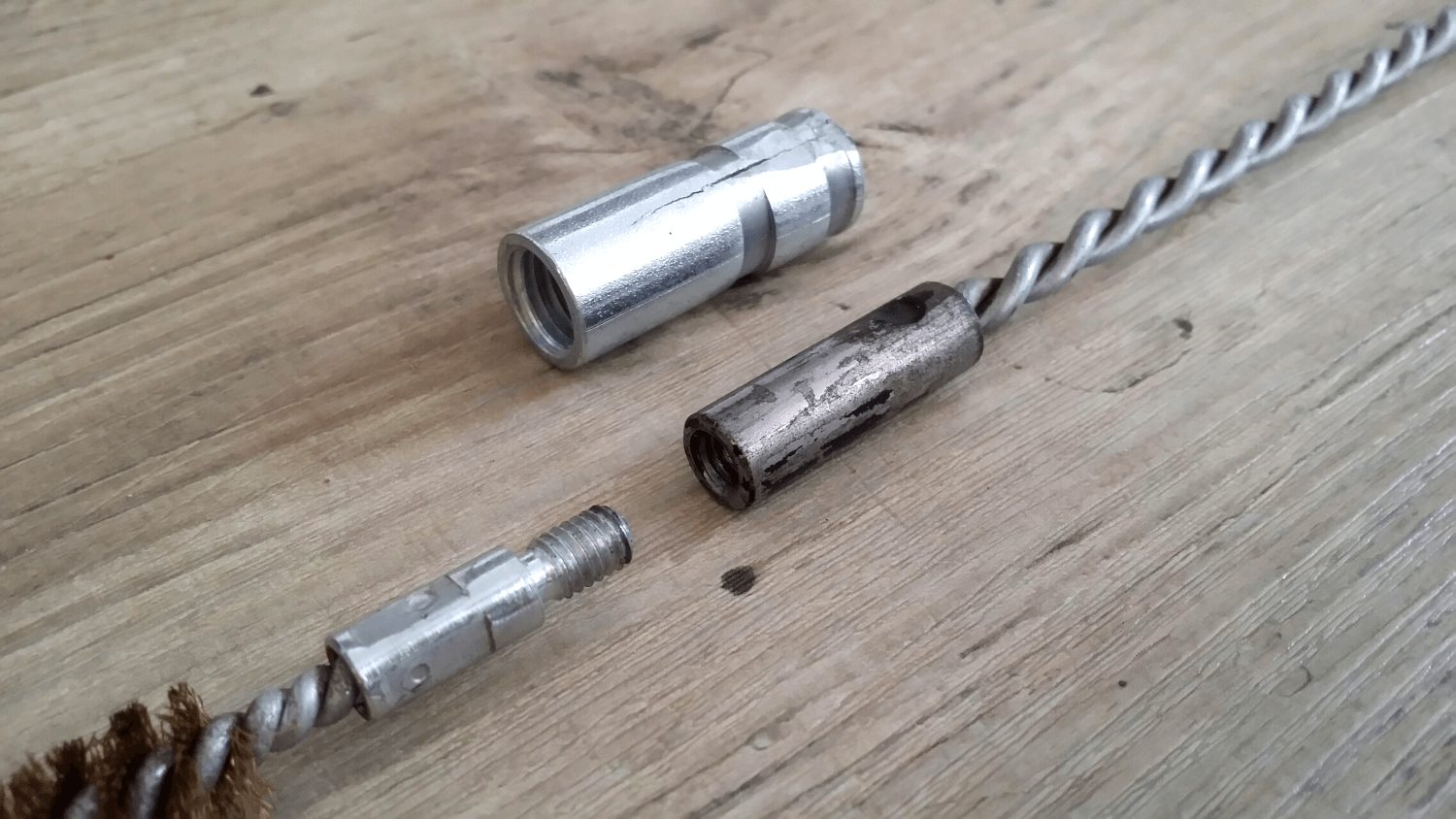

With both components (brush and rod) in hand, there was still one problem. The two didn’t connect since the brush’s threads are M6 male threads, whereas the rod was fitted with M12 female threads, with a total OD of a bit more than 14 mm – so it would not even fit through the tubes.

So that 14 mm nut had to be replaced with a smaller one that could fit through the tubes and take the brush with its M6 threads. The nut is pressed onto the rod in a slightly oval shape (see press-marks on Fig. 1), so to get rid of it, I hit it with a heavy hammer a few times on the ‘wider’ side. Initially, my intention was to keep the nut, but in the end, it cracked and ended up in the scrap pile.

For the new nut itself, I took a piece of 10 mm steel round stock with a length of about 30 mm. At first, I drilled all the way through the piece with a 5 mm drill bit. Then I widened the hole from one end to a 6 mm hole, about 17 mm deep. On this side, the rod was clamped on later. I was left with cutting the M6 threads and finally chamfered all edges to avoid scratches in the tubes.

In preparation to mount the nut on the rod, I flattened two (opposite) sides on the nut with a file and fitted the nut onto the rod. Finally, I took a flat punch and a heavy hammer to clamp the nut onto the rod - equally punching from both sides while checking if the rod was still situated at full stop inside the nut. The flattened sides helped to keep the punch a bit better in place when applying punctual forces with the hammer and punch.

When I first checked how the brush (mounted on the rod) fitted through the tubes, this wasn’t possible all the way through – its fit was too tight. I reduced the diameter of the brass brush by gently squeezing it in the vise while turning clockwise. After repeating this two times, I had a perfect fit.

With this setup, you can easily switch between brushes with different diameters if necessary. There is a whole range of different brushes with an M6 connection on the market. For example, I now can use it for the tubes of my 5″ steam locomotive as well.

I also recommend always turning the flue brush only clockwise if needed since this tightens the brush onto the rod (and the rod into the nut). Otherwise, you might end up with two parts – one inside and one outside the locomotive.

Surface Protection

Nut

If you attempt to protect the nut from corrosion, I’d recommend fireproof paint or blackening. My first coat of regular paint was gone after the first two operations. While fireproof paint is a bit more durable against scratching, it also wears over time. So my next attempt, when most of the paint is gone, will be oxidizing the nut chemically.

Handle

To prevent the handle from getting sooty quickly, I coated it with clear varnish. If the colour of the handle and the clean look are not so important, oil could also be an option, at least as water protection.

Finished Flue Brush

And that’s it, the finished flue brush with a flexible rod and a wooden handle.

Downloads

- Flue Brush Nut Drawing (*.pdf)